All Categories

Featured

Table of Contents

- – Rv Restoration Companies Ontario, CA

- – OCRV Center

- – Rv Restoration Companies Ontario, CA

- – Awnings For Trailers Ontario, CA

- – Rv Microwave Replacement Ontario, CA

- – Awning Installation Ontario, CA

- – Rv Sofa Beds Ontario, CA

- – Replacement Windows For Campers Ontario, CA

- – Replacement Windows For Rv Ontario, CA

- – Rv Microwave Replacement Ontario, CA

- – Rv Chairs Ontario, CA

- – Remodeling Rv Ontario, CA

- – Rv Dinette Booth Ontario, CA

- – Rv Sofas Ontario, CA

- – OCRV Center

Rv Restoration Companies Ontario, CA

Various other terms for this kind of home window seal can be glazing or home window trim. Instance of fixed window After you have actually confirmed your home window kind, currently it's time to locate the replacement seal. The very best means to establish what you need is to take a look at what gets on your motor home. Pull the window cut out of location so you can see the profile and take measurements.

This "photo" is an extremely crucial item to the problem. The second item of the puzzle is knowing the dimensions of your profile (see what locations you need to measure with the example photos below). Additionally, you'll need to have an approximate video footage in mind so you understand how much to buy.

When you're shopping online, keep in mind that some suppliers only supply their seals at a minimum or pre-cut lengths. That won't function for every task.

These chemicals can be harmful if not used appropriate If you do not have everything on this listing, we have actually got you covered! Begin by (thoroughly) removing the window. Area the window on a sheet covered table to protect against scraping.

Rv Restoration Companies Ontario, CA

Glue remover is especially useful below. It will certainly strip everything off the window frame consisting of any kind of adhesive that might have been Clean the motor home frame, or channel where the home window rests. You will want a clean surface for your new seal As soon as whatever is tidy, take your brand-new seal and press right into location.

Gaskets will certainly make an audible sound when they have actually broken into place. Something else to note: some installments might need you to remove the glass from the home window structure.

Awnings For Trailers Ontario, CA

After the glass is gotten rid of, the seal setup ought to be the exact same as outlined above. If you have questions relating to weatherstripping for your traditional car, street pole, RECREATIONAL VEHICLE, or watercraft, don't wait to contact us!

Recreational vehicle home window replacement is just one of the most convenient diy tasks. All you do is eliminate a few screws, pop the old home window out, use sealant, and stand out the new window in. Of training course there are a couple of extra actions, which we'll get to in a moment, however that's the standard treatment.

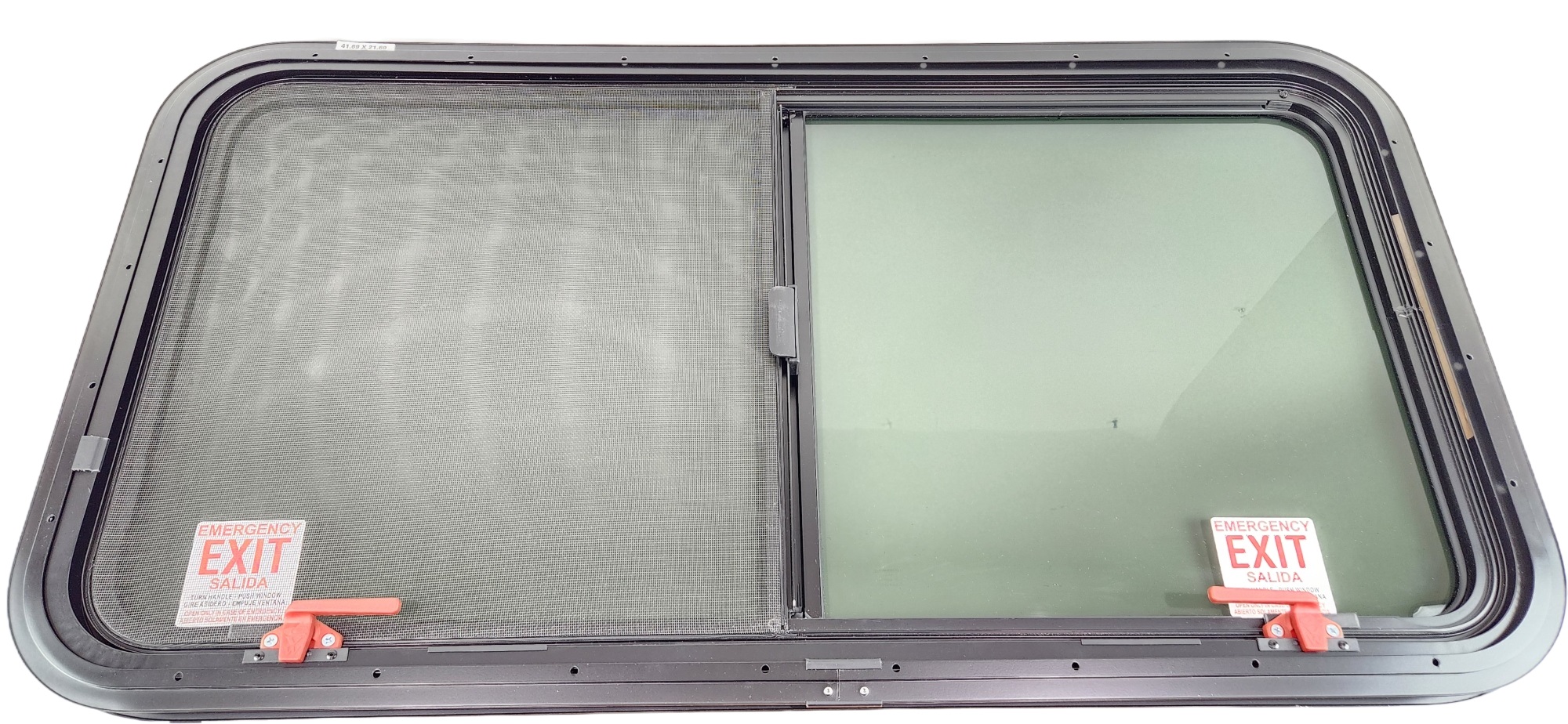

You can go with a various window kind if you like. Substitute choices include fixed pane, moving pane, jalousie, awning, frameless, and egress. If you want much better insulation from the warmth and the chilly, you can update from solitary pane to double pane home windows. There are additionally numerous shades and shades of tinting that can be applied to the window.

Precisely determining the dimensions of your old home window, or your window opening, is important when buying replacements. Many camper windows are customized made, and returns are usually declined. Fixed pane/awning window combination by Kinro The bulk of motor home home windows are clamp ring placed. That means the RV sidewall is sandwiched between an outside window framework and an indoor trim ring.

Rv Microwave Replacement Ontario, CA

Pressure holds the window in location. One person can replace a home window, though it will certainly be bit less complicated with two individuals, especially if it's a huge home window.

If you're replacing all the windows on your camper, you'll possibly cut off several of that time after doing a couple. We're reader-supported. When you buy with links on our website, we may earn an associate payment. Philips Screwdriver Putty Blade, Scrape Tool, or Flat Head Screwdriver Silicone Sealer Spray Container of Water Ruler or Tape Procedure Tape, if no assistant is available (blue painter's tape works best) The first 3 steps involve getting rid of the old home window and sealant From inside the motor home, start by eliminating the drapes and blinds.

Awning Installation Ontario, CA

Now you'll eliminate the screws from the inside window trim ring. There will certainly be 12 or more screws right here. Prior to removing the last few screws, you'll need an assistant to stand up the home window on the outdoors to stop it from dropping to the ground. If no helper is readily available, tape can be use to hold up the home window.

Even more than likely, the home window will still be kept in place by caulking and putty tape. Currently you'll relocate outside the RV, and with a putty blade under the outside window flange, meticulously tear the home window out from the sidewall. It aids to have an additional individual keep the home window while you tear it out.

A tidy surface area will certainly give a better hold for the new putty tape and caulking, and make a much better seal. Currently it's time to appear that shiny brand-new RV window and secure the offer Dry fit the new recreational vehicle home window initially, to make sure it fits appropriately. Do this by placing the home window in the opening, with no putty tape.

Rv Sofa Beds Ontario, CA

If there is much less overlap on top, you'll require to utilize shims to raise the home window up from the bottom. The window needs to be centered in the home window opening, both vertically and flat.

Apply the supplied putty tape to the Motor home sidewall around the boundary of the home window opening. You do not want any type of voids for water to slip in between the outside window flange and the RV sidewall.

This will certainly protect against the home window from sticking to the putty tape, offering you some time to focus the home window. Now mount the window, centering it in the window opening.

When the screws are tightened up, go outside and examine that there are no gaps in the putty tape. For extra insurance coverage against water damage, use a bead of clear silicone sealer around the window structure.

Replacement Windows For Campers Ontario, CA

A motor home is component home and part automobile, and often, after the "residence" has actually been driven for miles and miles over bumpy roads, upkeep problems can emerge. Among the possible fixings that a recreational vehicle owner might deal with is a RV home window replacement. We faced this concern numerous years back and fulfilled it head-on with our need to DIO (Do It Ourselves) as several of our own RV repair and maintenance jobs as possible.

These are the tools we needed for our camper window replacement. Depending on your Motor home, you may or might not require all of these devices for your task.

No issue where you acquire your brand-new RV window, you'll require to give exact measurements. Let's damage down our procedure for measuring a Motor home home window for substitute.

Replacement Windows For Rv Ontario, CA

Do not place any type of outside stress on the window while taking your dimensions or it might come loose and fall. For extra safety, you may wish to have a helper on a ladder outside, holding the window in area while you measure. Carefully remove the structure of your old home window to ensure that you can gauge the opening (NOT the window itself).

For our rectangular window, we required to take just 4 measurements. Please keep in mind that we're gauging the opening itself. Making use of a measuring tape, take careful note of the size and height of the opening. It's a good idea to take dimensions at a number of points so you have a concept of how cleanly the home window opening was reduced.

Rv Microwave Replacement Ontario, CA

Measurements of the old window and the home window opening are usually different. Window suppliers use filler strips to keep the window level and snug.

Action twice, cut as soon as? Take your time to obtain an exact dimension, and double-check it by determining a second time. Precise dimensions are essential to RV home window replacement. We do not intend to freely gauge and round up or down. Always gauge to the nearest 1/16th of an inch. Take a close take a look at your measuring tape and make certain you know which are the 1/16th-inch dimensions.

Rv Chairs Ontario, CA

The window suppliers are the ideal authorities on mounting their products. The producer of your new recreational vehicle window has most likely included handy guidelines or tips to make the setup less complicated. These kinds of guidelines are often consisted of on makers' sites as well. If your new home window came with instructions in the plan, make sure to maintain those useful as they might have outlined step-by-step directions in a consisted of brochure.

There may be a bead of sealant around the top of your old window or in between the external home window framework and the motor home's sidewall. If so, you'll need to eliminate this before eliminating the old home window. Relocating to the beyond the RV, use your plastic putty blade (yes PLASTIC, to stay clear of damaging your recreational vehicle's coating) to thoroughly break the seal around the old home window and eliminate it.

Remodeling Rv Ontario, CA

Make certain the window is OPEN to make sure that you can strongly comprehend the window as it falls out of the opening, once the seal is broken. Remove any kind of staying sealant utilizing your plastic putty blade, and wipe any staying particles utilizing mineral spirits. Give the area a last cleansing using scrubing alcohol to make sure that the area around the window opening is devoid of any kind of oily residue.

Begin by establishing your brand-new window on a flat surface area covered with a soft fabric, with the outside of the home window encountering down. Clean completely around the side with rubbing alcohol and a clean cloth. This will make sure that the surface area is free from all residue. Making use of the consisted of roll of double-sided, closed-cell foam tape, use the tape.

Rv Dinette Booth Ontario, CA

Dimensions of the old home window and the window opening are usually different. Home window producers make use of filler strips to maintain the window degree and snug.

Take your time to get a precise measurement, and verify it by gauging a 2nd time. Specific dimensions are crucial to Motor home home window substitute. Take a close appearance at your tape measure and be sure you understand which are the 1/16th-inch measurements.

The home window suppliers are the finest authorities on mounting their items - Rv Couch Ontario. The supplier of your brand-new Motor home window has most likely included valuable standards or suggestions to make the setup much easier.

Rv Sofas Ontario, CA

There may be a grain of sealer around the top of your old home window or between the outer window frame and the recreational vehicle's sidewall. If so, you'll require to remove this prior to getting rid of the old window. Relocating to the beyond the RV, use your plastic putty knife (yes PLASTIC, to avoid scratching your RV's coating) to meticulously damage the seal around the old home window and eliminate it.

Make sure the window is OPEN so that you can securely grasp the window as it befalls of the opening, as soon as the seal is damaged. Remove any kind of continuing to be sealer utilizing your plastic putty knife, and cleanse off any kind of remaining debris using mineral spirits. Offer the location a last cleaning utilizing massaging alcohol to make sure that the area around the window opening is devoid of any oily deposit.

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: art@ocrvcenter.com

OCRV Center

Begin by setting your new home window on a flat surface covered with a soft cloth, with the exterior of the home window encountering down. Making use of the included roll of double-sided, closed-cell foam tape, use the tape.

Rv Interior Furniture Ontario, CARv Replacement Awnings Ontario, CA

Rv Interior Remodel Ontario, CA

Replacement Rv Windows Ontario, CA

Motorhome Carpets Ontario, CA

Rv Replacement Furniture Ontario, CA

Replacement Windows For Rv Ontario, CA

Rv Replacement Awnings Ontario, CA

Rv Floor Replacement Ontario, CA

Awnings For Rv Ontario, CA

Rv Couch Ontario, CA

Replacement Rv Windows Ontario, CA

Rv Dinette Booth Ontario, CA

Replace Rv Flooring Ontario, CA

Rv Floor Replacement Ontario, CA

Rv Interior Remodel Ontario, CA

Rv Replacement Awnings Ontario, CA

Replacement Rv Refrigerator Ontario, CA

Rv Replacement Awnings Ontario, CA

Remodeling Rv Ontario, CA

Rv Restoration Companies Ontario, CA

Rv Sofa Sleeper Ontario, CA

Rv Sofas Ontario, CA

Rv Restoration Companies Ontario, CA

Rv Couch Bed Ontario, CA

Awning Installation Ontario, CA

Rv Couch Bed Ontario, CA

Awnings For Rv Ontario, CA

Rv Dining Table Ontario, CA

Rv Carpet Installation Ontario, CA

Remodeling Rv Ontario, CA

Rv Couch Ontario, CA

Awnings For Trailers Ontario, CA

Rv Couch Ontario, CA

Rv Floor Replacement Ontario, CA

Rv Couch Ontario, CA

Rv Sofa Beds Ontario, CA

Awning Installation Ontario, CA

Rv Sofa Beds Ontario, CA

Rv Carpet Replacement Ontario, CA

Rv Chairs Ontario, CA

Rv Chairs Ontario, CA

Awnings For Rv Ontario, CA

Replacement Windows For Campers Ontario, CA

Rv Refrigerator Replacement Ontario, CA

Rv Interior Remodel Ontario, CA

Rv Microwave Replacement Ontario, CA

Rv Floor Replacement Ontario, CA

Rv Interior Remodel Ontario, CA

Rv Chairs Ontario, CA

Replacement Rv Refrigerator Ontario, CA

Rv Couch Ontario, CA

Rv Chairs Ontario, CA

Rv Carpet Replacement Ontario, CA

Rv Carpet Replacement Ontario, CA

Rv Couch Ontario, CA

Rv Replacement Awnings Ontario, CA

Rv Dining Table Ontario, CA

Rv Chairs Ontario, CA

Awnings For Rv Ontario, CA

Remodeling Rv Ontario, CA

Replacement Windows For Rv Ontario, CA

Rv Sofa Sleeper Ontario, CA

Rv Microwave Replacement Ontario, CA

Awnings For Trailers Ontario, CA

Rv Restoration Companies Ontario, CA

Rv Replacement Awnings Ontario, CA

Rv Dinette Table Ontario, CA

Rv Floor Replacement Ontario, CA

Rv Chairs Ontario, CA

Rv Refrigerator Replacement Ontario, CA

Rv Couch Bed Ontario, CA

Replacement Windows For Rv Ontario, CA

Motorhome Carpets Ontario, CA

Awnings For Trailers Ontario, CA

Rv Restoration Companies Ontario, CA

Rv Restoration Companies Ontario, CA

Rv Refrigerator Replacement Ontario, CA

Near You Seo Packages Ontario, CA

Finding A Local Seo Firm Ontario, CA

OCRV Center

Table of Contents

- – Rv Restoration Companies Ontario, CA

- – OCRV Center

- – Rv Restoration Companies Ontario, CA

- – Awnings For Trailers Ontario, CA

- – Rv Microwave Replacement Ontario, CA

- – Awning Installation Ontario, CA

- – Rv Sofa Beds Ontario, CA

- – Replacement Windows For Campers Ontario, CA

- – Replacement Windows For Rv Ontario, CA

- – Rv Microwave Replacement Ontario, CA

- – Rv Chairs Ontario, CA

- – Remodeling Rv Ontario, CA

- – Rv Dinette Booth Ontario, CA

- – Rv Sofas Ontario, CA

- – OCRV Center

Latest Posts

Web Design Services Near Me Norco

Best Local Seo Glendora

Local Seo Companies Corona

More

Latest Posts

Web Design Services Near Me Norco

Best Local Seo Glendora

Local Seo Companies Corona